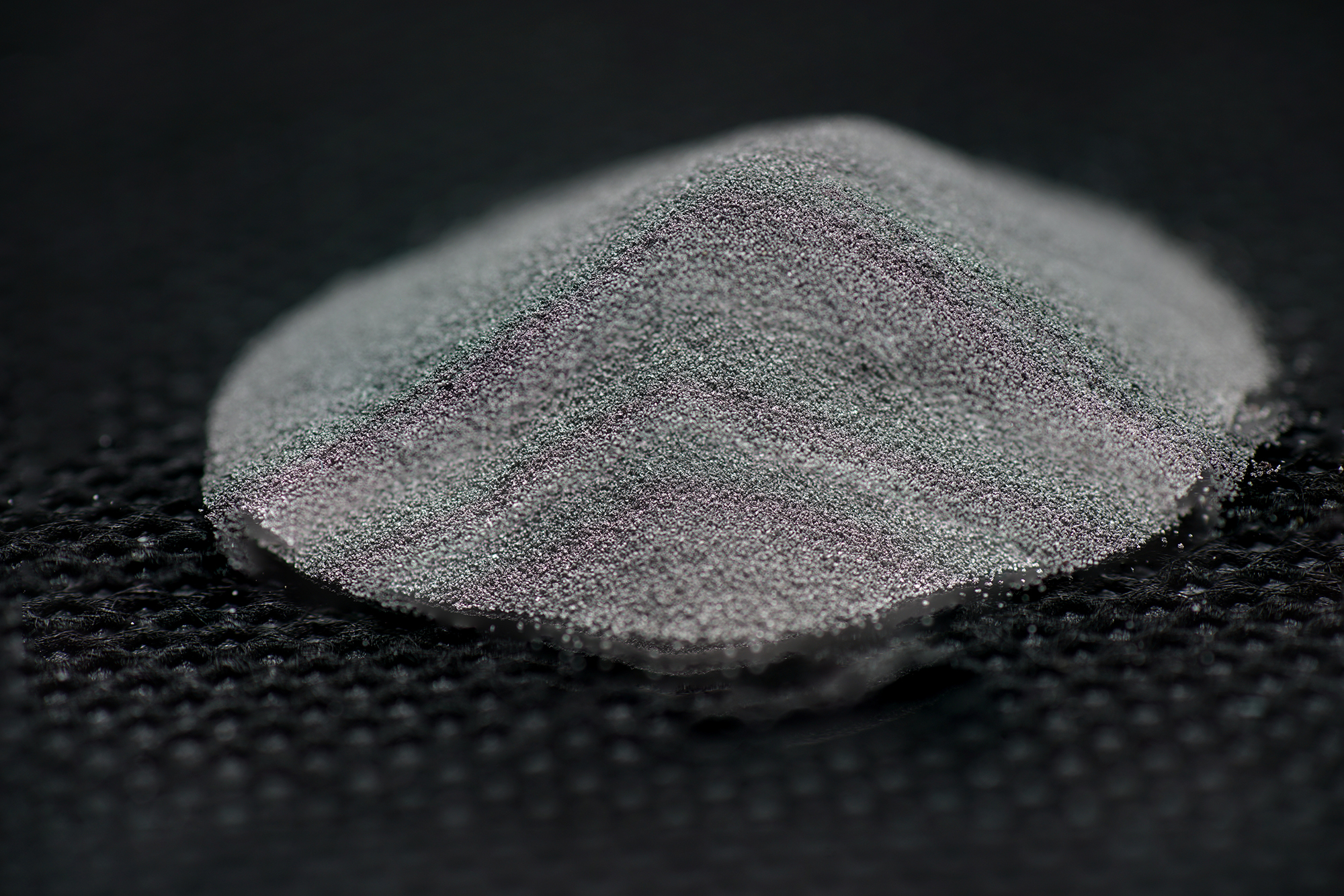

Picture this: microscopic iron particles, seemingly insignificant, yet playing a crucial role in various industries. These particles, known as iron powder, are a versatile material used in everything from car parts to advanced materials. Let’s delve into the world of iron powder, exploring its properties, applications, and sourcing strategies.

Unveiling the Versatility of Iron Powder

Iron powder isn’t simply rust. Imagine finely ground iron, similar to flour but metallic. These tiny particles, typically 20 to 200 micrometers (smaller than a hair’s width!), possess remarkable magnetic, chemical, and mechanical properties. These properties vary based on the iron’s purity, production method, and even particle shape and size, opening a wide range of applications across diverse industries.

Where Iron Powder Makes a Difference

Iron powder quietly contributes to countless everyday items and cutting-edge technologies:

- Automotive: Iron powder is integral to various car parts, including brakes, suspension systems, and certain engine components.

- Powder Metallurgy: This process, akin to baking with metal, mixes iron powder with other materials, presses it into a mold, and heats it to create intricate parts like high-precision gears.

- Magnets: Iron powder is a key component in many soft magnetic materials, including those used in magnetic paints and coatings, often powering those fridge magnets we all rely on.

- Brazing: Acting as a metallic glue, iron powder facilitates strong bonds between metal pieces during the brazing process.

- Food Fortification: Surprisingly, iron powder fortifies foods with iron, combating iron deficiencies.

- Printing: From pen ink to printer toner, iron powder contributes to sharp, clear images and text.

Looking for an effective way to keep unwanted visitors out of your property? Look no further than our impressive range of keep out signs.

Creating Iron Powder: A Look at the Processes

Producing iron powder involves more than just grinding iron. Different techniques yield powders with distinct characteristics:

- Water Atomization: Molten iron is sprayed with powerful water jets, creating tiny droplets that cool and solidify into smooth, spherical particles.

- Chemical Reduction: Gases react with iron oxides (like rust), removing oxygen and leaving behind irregularly shaped, porous iron particles – a kind of reverse rusting.

- Electrolysis: Electricity extracts pure iron from an iron salt solution, resulting in highly pure, spherical particles.

Defining Factors in Iron Powder Performance

Not all iron powders are equal. Several factors influence their performance:

- Purity: Higher purity generally translates to better performance, especially in magnetic components or food additives.

- Particle Size Distribution: The size range of particles affects flow, packing density, and final product properties.

- Density: The packing density of particles influences the final product’s density and overall characteristics.

The Evolving Landscape of Iron Powder

Ongoing research continuously expands the potential of iron powder:

- Additive Manufacturing: Iron powder may improve 3D printing with metal, leading to stronger, lighter, and more complex parts.

- Hydrogen Storage: Studies suggest its potential role in storing hydrogen gas, crucial for cleaner energy.

- Sustainable Production: Research focuses on environmentally friendly production methods.

Unlocking the Potential of Powdered Iron: Industrial, Scientific, and Everyday Applications

Powdered iron, a versatile material, quietly powers numerous products and industries. One prominent application is in automotive braking systems, where it provides essential friction in brake pads. Powder metallurgy utilizes powdered iron to create complex-shaped parts, offering advantages over traditional machining. Welding and brazing benefit from its ability to act as a filler material and fluxing agent. Powdered iron’s magnetic properties are critical in electromagnetic devices, while its thermal properties make it suitable for protective coatings. Surprisingly, it also fortifies food with iron and contributes to the clarity of printed text and images. Ongoing research points towards even more diverse future applications.

| Application | How it’s used |

|---|---|

| Automotive Brakes | Provides friction material in brake pads and linings |

| Powder Metallurgy | Creates complex-shaped metal parts like gears and bearings |

| Welding/Brazing | Acts as a filler material and fluxing agent for stronger joints |

| Magnetic Products | Forms the core of inductors, transformers, and electromagnetic devices |

| Surface Coatings | Protects components in high-temperature environments from corrosion and wear |

| Food Fortification | Added to food to prevent iron deficiency |

| Printing | Used in toners and inks for color and clarity |

Is Iron Powder Safe to Handle and Use? Risks, Benefits, and Precautions

While generally safe, handling powdered iron requires understanding its nuances. The particle size significantly influences potential hazards, especially flammability and inhalation risks. Different types of powdered iron also present varying safety concerns.

Safe Handling Practices:

- Ventilation: Work in a well-ventilated area to prevent dust buildup.

- Protective Gear: Use respirators, gloves, and eye protection.

- Storage: Store in a cool, dry place away from ignition sources.

- Careful Handling: Avoid creating dust clouds.

- Proper Disposal: Follow local regulations.

Special Considerations:

- Powder Coating: Some additives in powder coatings may be toxic; consult safety data sheets.

- Iron Supplements: Follow recommended dosages and consult a healthcare professional.

- Industrial Uses: Adhere to specific safety guidelines for your application.

Ongoing research on long-term exposure effects emphasizes the importance of precautions. While generally considered safe with proper handling, potential unknown risks warrant caution.

| Pros | Cons |

|---|---|

| Versatile material with many applications | Potential fire hazard if not handled carefully |

| Relatively inexpensive | Inhalation risks, especially with fine powders |

| Easy to process and manipulate | Can react with other substances |

Unlocking the Power of Iron Powder: Health, Industrial, and Environmental Benefits

Iron powder contributes significantly to various fields. It’s a readily available source of iron, essential for oxygen transport, immune function, and energy levels. Studies suggest its potential to alleviate fatigue and improve cognitive function, particularly in cases of iron deficiency. Athletes may benefit from improved oxygen delivery to muscles. Industrially, iron powder strengthens steel, enables magnet production, creates vibrant pigments, and acts as a catalyst. It also finds use in food supplements, cosmetics, and even fireworks.

| Category | Application | How it works |

|---|---|---|

| Health | Iron supplement | Replenishes iron levels |

| Health | Fatigue reduction | Supports oxygen transport and energy production |

| Health | Cognitive function | Essential for brain processes |

| Health | Athletic performance | Improves oxygen delivery to muscles |

| Industrial | Steel production | Enhances strength and quality |

| Industrial | Magnet production | Provides magnetic receptivity |

| Industrial | Pigment production | Acts as a colorant |

| Industrial | Catalyst production | Facilitates chemical reactions |

| Other | Food supplements | Increases iron content |

| Other | Cosmetics | Adds a metallic finish |

| Other | Fireworks | Creates sparks |

While iron powder offers numerous benefits, ongoing research continues to explore its long-term impacts. The effects of supplementation can vary, and consulting a healthcare professional is crucial before starting any new regimen, especially for individuals with underlying health conditions.

Key Points About Iron Powder:

- Versatile material with unique magnetic, chemical, and mechanical properties.

- Used in diverse industries, including automotive, powder metallurgy, magnets, brazing, food, and printing.

- Produced via water atomization, chemical reduction, or electrolysis, each yielding powders with different characteristics.

- Performance is influenced by purity, particle size distribution, and density.

- Shows promise for advancements in additive manufacturing, hydrogen storage, and environmentally friendly production.

- High Magnetizability and Permeability make it ideal for magnetic applications, especially in narrow-band circuits where temperature stability is crucial (compared to ferrite cores).

- High density is beneficial for weight-sensitive applications.

- Excellent Electromagnetic Properties lend themselves to specific uses.

- High heat resistance makes it vital in thermal surface coatings to protect against corrosion and wear.

- Different types of iron powder exist (reduced, atomized, electrolytic) each with varying properties impacting safety and applications.

- Flammability, especially in fine powders, poses a risk.

- Inhalation hazards require precautions, including adequate ventilation and respirators.

- Reactivity with oxidizing agents and acids can occur.

- Iron plays a vital role in the body, involved in oxygen transport, growth, energy, hormone synthesis, and neurological development.

- Calcium can inhibit iron absorption, so avoid high-calcium foods/drinks with iron supplements. Plant-based milk is a better alternative.

Remember ongoing research likely suggests evolving conclusions about its properties, applications, and safety. Some theories are still being explored. It’s important to consult with experts and refer to updated research for the most current information.

- Divided Lunch Containers Revolutionize Your Meal Prep Strategy - February 9, 2026

- Divided Food Storage Containers Transform Meal Prep and Portion Control - February 8, 2026

- Divided Food Containers Are Meal Preps Secret Weapon - February 7, 2026